Coiled Tubing

Automated Injector Heads and Spooling Systems for Autonomous Operations

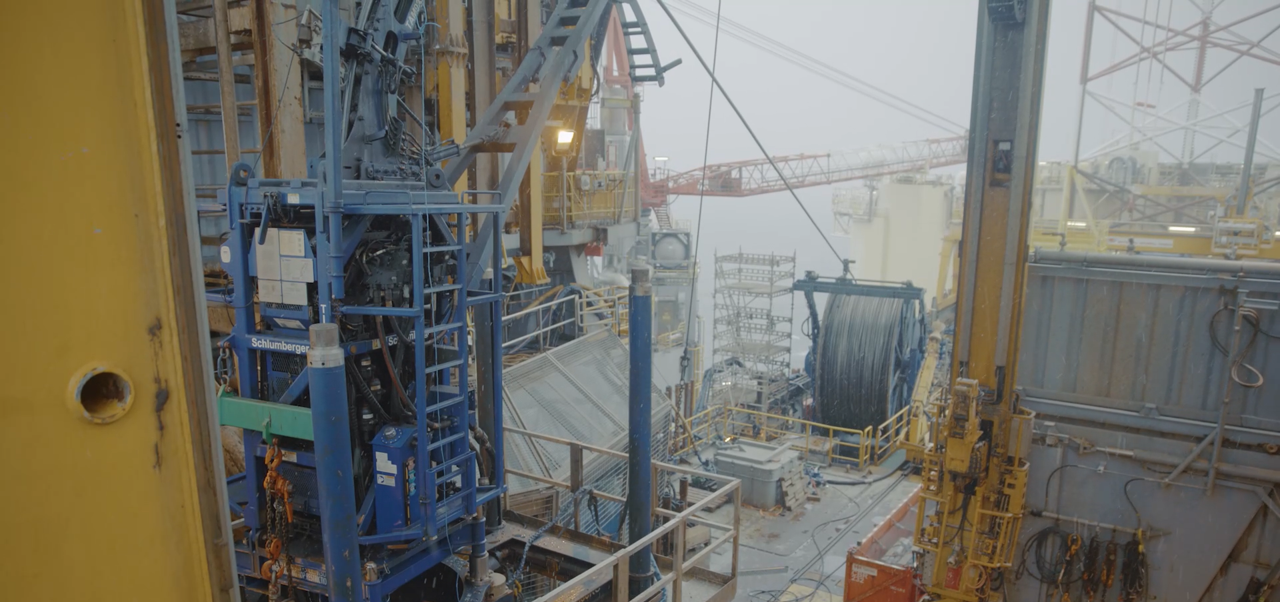

Coiled tubing systems for the most demanding offshore operations.

Stimline’s digital ecosystem enables Intelligent Conveyance™ seamlessly integrated with digital workflows, laying the foundation for autonomous operations supported by advanced data science.

With Stimline your coiled tubing units are prepared for any operational challenge.

Individual components or the full deal?

Stimline delivers injector heads, control system upgrades and spooling systems, individually or part of a package upgrade. We also offer offshore reel systems. Additional products, such as cabins, power units, well control, pumping and fluid systems can be delivered and integrated to form complete offshore coiled tubing spreads.

Explore Coiled Tubing Products

Want all the details?

IHX130 Injector Head

Proven in demanding, deep record-setting operations for years

IHX130 Injector Head is designed for the most challenging and deeps wells in the world.

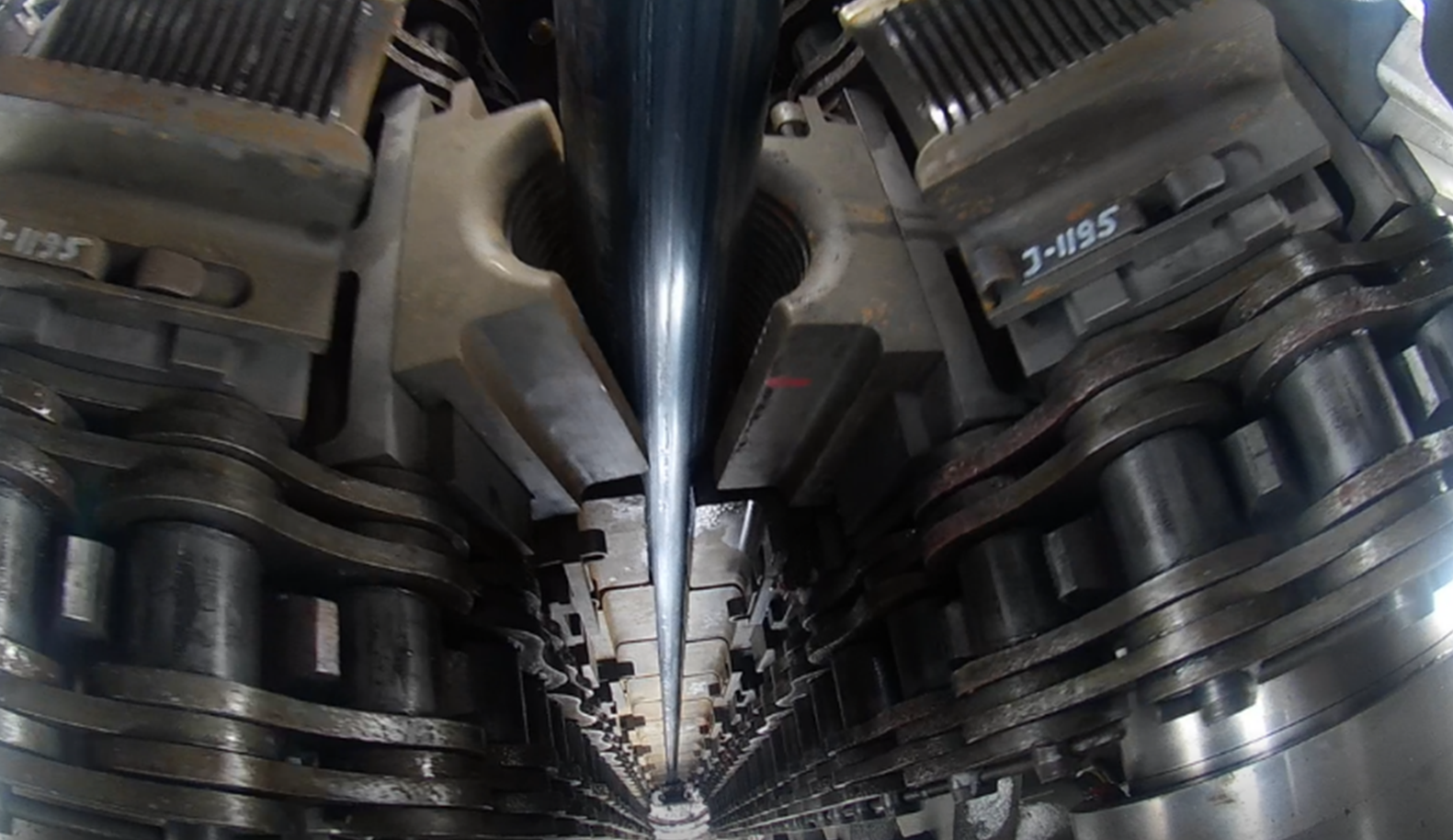

The patented Stimline design is engineered for challenging, deep wells using large, heavy-wall tubing. Key features are proven over millions of meters, significantly reducing tubing wear and enhancing safety. Its core unique technologies include:

Patented Floating Tubing Traction System: Optimizes the rotation center to improve weight reading and minimize pipe wear.

Patented Reversible One-Plate Skate Design: Features an optimized shape that reduces loads on both the tubing and rollers.

Integrated tubing suspension system in skate blocks reduce pipe wear and improves friction.

Unique IHX130 Automation Kit: Continuously and automatically optimizes traction and chain tension forces, rapidly adapting to changing hole conditions

Injector Automation provides rapid response to changing hole conditions automatically.

Active Traction continuously optimizes skate pressure for peak traction and minimal tubing fatigue

Active Traction automatically responds to changing hole (weight) conditions

Active Traction automatically detects and responds to changing hole conditions, slips, run-aways, or system failures.

Active Chain Tension automatically adjust force to weight and tubing direction

Active Reel Tension automatically adjust back-tension to the injector weight, speed and accelerations

The Injector Automation Kit turns the IHX130 into an intelligent injector, operating with the optimized parameters, rapidly reacting to changing hole conditions.

The IHX130 is the perfect partner to our Intelligent Conveyance™ technology.

The perfect companion for autonomous operations.

Tightly connected with FIXX Autonomy Platform, enabling pre-defined run planning and execution, taking into account best practices, wellbore conditions and reactions to events

Compatible with use of downhole sensors to control the surface IHX130 where applicable

Interface possibilities with third-party Well Control Systems

Can be interfaced with pumping / flow back systems for optimized drilling / milling operations

The IHX130 is designed as a vital part of our Intelligent Conveyance™ technology, forming an integral part of completely autonomous coiled tubing intervention or completion systems.

Operated from multiple locations, providing operational and organizational flexibility

XOS operator station in the coiled tubing operator cabin.

XOS operator panel located in an “ice-box” or platform office.

The driller’s chair, integrated with the rig’s drilling control system.

Wireless rigging panel.

XOS Remote System.

Autonomy enabled and digital ready with the FIXX Autonomy Platform

Our coiled tubing equipment meets and exceeds all NORSOK capacity and performance requirements.

International versions are available where NORSOK standards are not required.

Made for offshore operations, fully conform to NORSOK requirements

Delivered with Guide Arch.

Foldable in to two sections

Remote locking mechanism, no need to climb

Dimensioned according to recognized standards

Designed for high grade heavy wall large OD tubing

Adjustable centerline

Steel rollers

Optional load cell measuring coil back tension

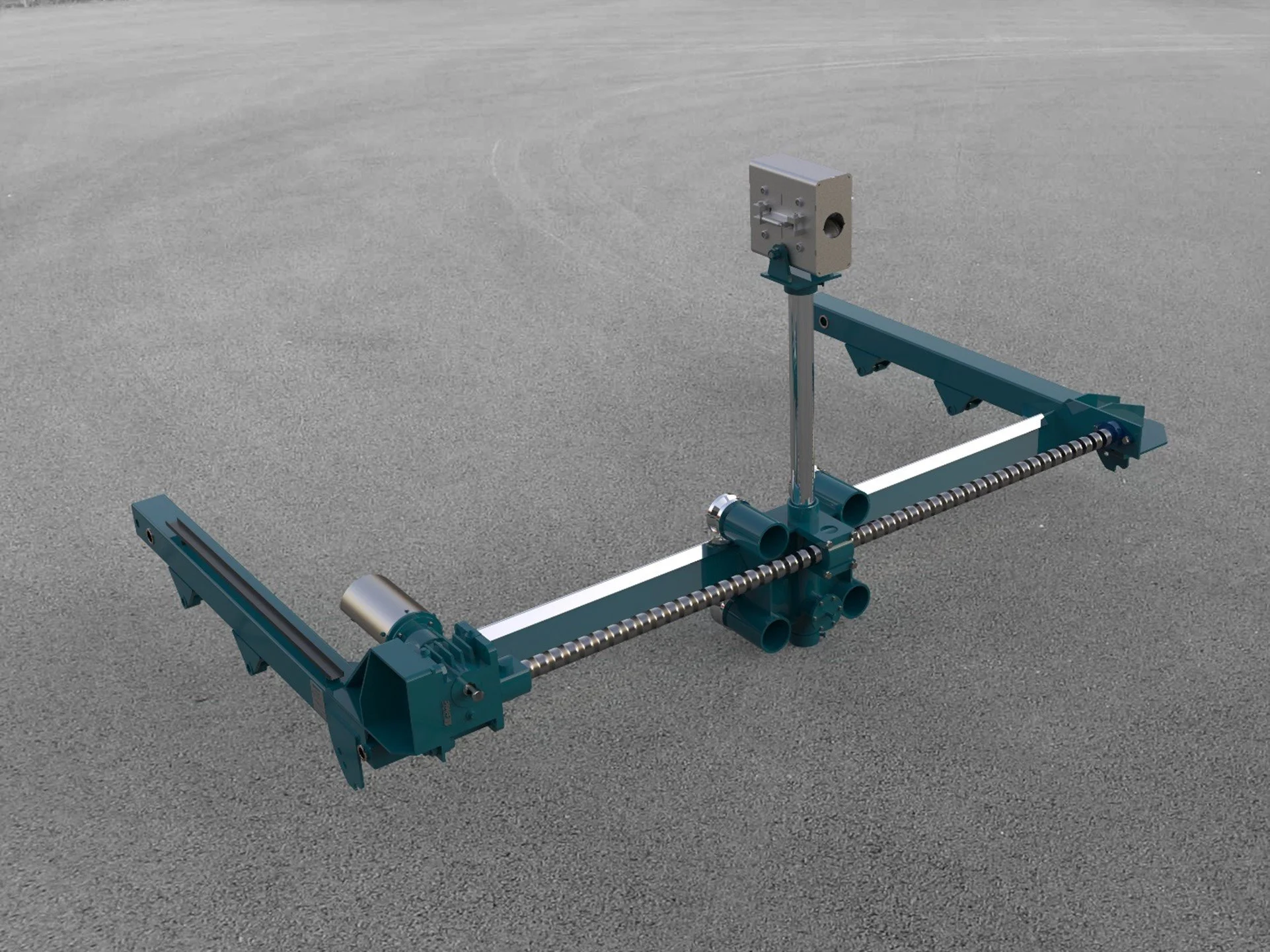

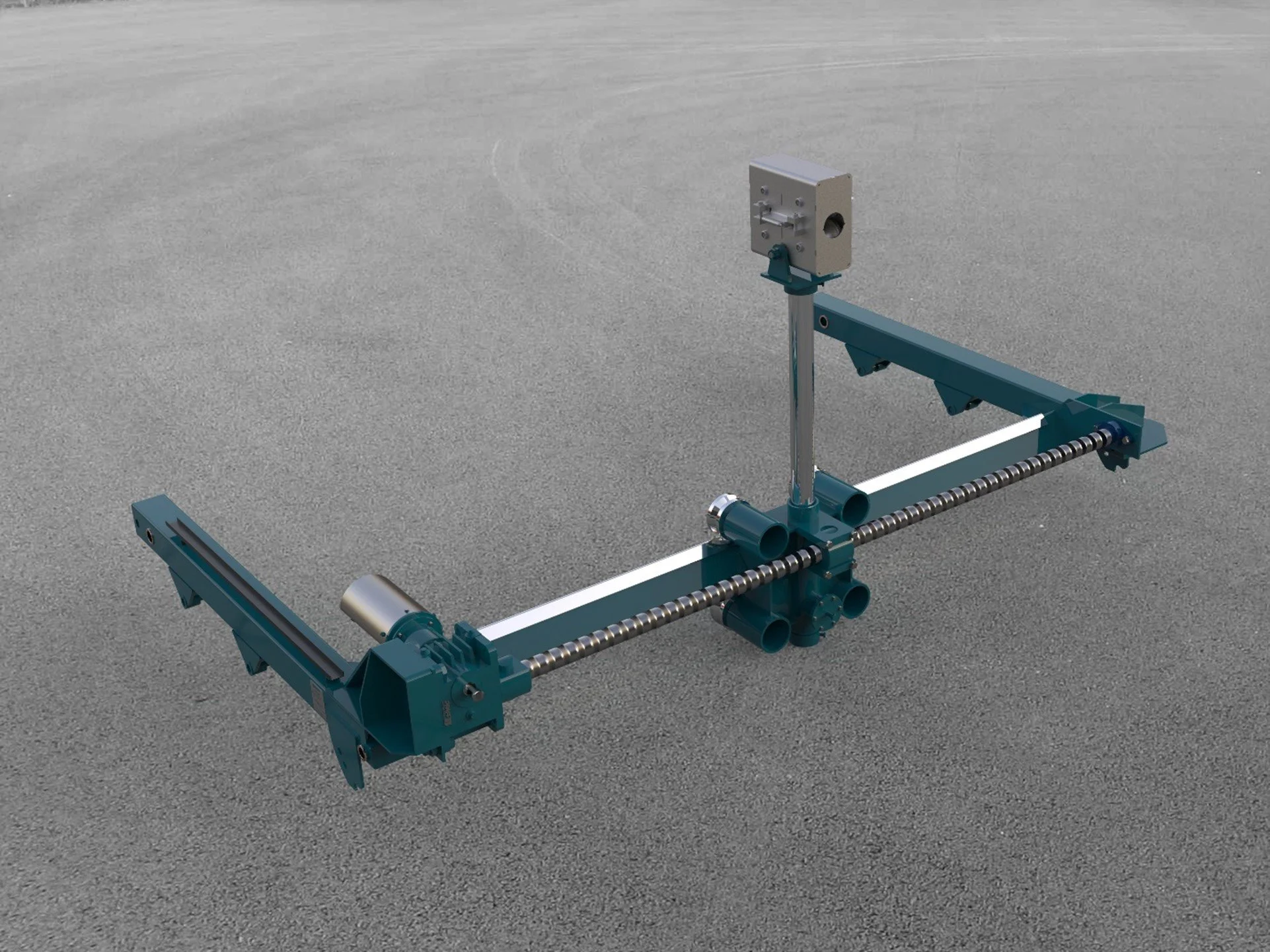

Electric Levelwind with Auto Spooling Option

Designed for large tubing sizes, the electric level wind provides optimal spooling

World’s first electric levelwind.

The electric levelwind enables active and continuous positioning of tubing, spooling on or off the reel. The tubing managment system calculates the optimal placing of tubing based on reel rotation, back tension and other parameters.

Electric Levelwind stand out features

Electric drive and motor combination provide accurate positioning and position feedback without external sensors

Force and motion designed for spooling large, heavy wall, high grade tubing

Guide Head designed to actively steer the tubing sideways when required to spool correctly

High precision design

Can be outfitted with passive Counter Head

Upgrade your existing spooling operation

The Electric Level Wind with auto spooling control system can be retro-fitted to most existing reel systems, such as Power Stand.

Coiled Tubing Pricing

Want to get an indicative proposal or quote for your project?